The goal of every project is to balance quality, time, and cost. But how can this be achieved in an industry faced with limited resources, complex requirements, and tight schedules? One possible answer lies in the application of lean principles.

Although this approach originally stems from the automotive industry, it can be effectively applied to virtually any sector. This guide will introduce you to the five key lean principles and explain how they especially benefit the construction industry.

- Lean Management and the Lean principles: definition

- The 5 Lean principles in detail

- Benefits of Lean Management principles in construction

- Challenges in implementing Lean principles

- Agile construction management based on Lean principles

- Ready for the future with Lean principles

- FAQ – Frequently asked questions on Lean Management principles

Lean principles at a glance

What is Lean Management?

A method to streamline processes by reducing waste and continuously improving efficiency, time, and cost without sacrificing quality.

Where can Lean be applied?

Across industries – construction, healthcare, administration, leadership, and more.

What are the 5 Lean Principles?

1. Define value from the customer’s perspective.

2. Identify the value stream.

3. Optimise the flow of processes.

4. Pull – Align work with customer demand.

5. Strive for perfection (Kaizen).

Why use Lean in construction?

To finish projects faster, cut costs, improve quality, enhance collaboration, and build sustainably.

What’s needed to implement Lean?

Teamwide understanding, strong leadership, cultural change, and a tailored approach to each company.

Lean Management and the Lean principles: definition

“Lean” refers to a concept focused on process optimisation. In short, it involves reducing all operations to what is essential. Within the lean context, two terms are particularly important:

Lean Management

Lean Management refers to corporate or project leadership based on the lean concept – that is, the avoidance of waste and the continuous improvement of all processes. The aim is to reduce time and costs as much as possible while maintaining or even enhancing quality.

What does Lean Management mean for the construction industry?

By applying lean management principles and methods, construction companies can complete projects faster, reduce overall costs, and improve the quality of their builds.

Lean principles

Lean principles – also known as lean management principles or agile principles – are the fundamental ideas behind lean management aimed at improving efficiency. They are based on the Toyota Production System (TPS) and focus on minimising waste while maximising customer value.

The 5 lean principles are:

- Value – Define value from the customer’s perspective

- Value Stream – Identify the value stream

- Flow – Optimize the flow of processes

- Pull – Align production with customer demand

- Perfection (Kaizen) – Strive for continuous improvement

Of course, these brief labels alone reveal very little. That’s why we’ll explore the lean principles in greater depth in the next chapter. But first, one question remains: where are lean’s agile principles actually used?

Lean across all sectors: Lean Production, Lean Leadership & more

The lean approach can be applied across a wide range of industries and roles – essentially, anywhere there are processes that can be optimised. While lean production at Toyota marked the beginning, today we speak of many more areas of application:

The lean approach can be applied across a wide range of industries and roles – essentially, anywhere there are processes that can be optimised. While lean production at Toyota marked the beginning, today we speak of many more areas of application:

Would you like to explore how lean principles are applied specifically in construction?

As industry specialists, we’ve gathered all the essential insights into Lean Construction in a comprehensive guide tailored to the building sector.

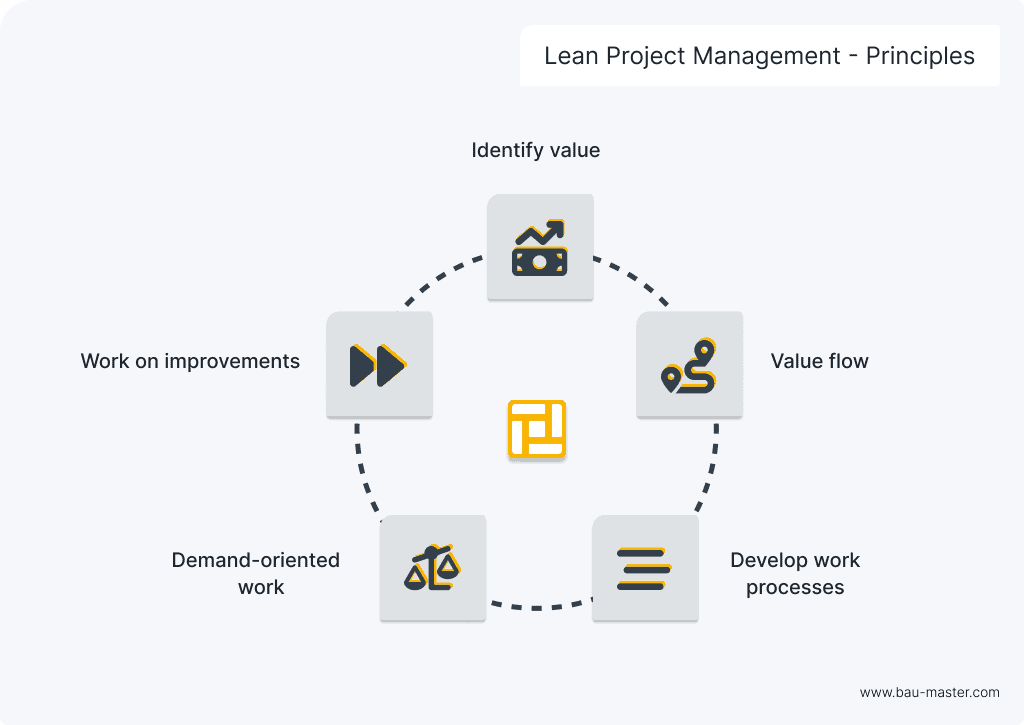

The 5 Lean principles in detail

Defining customer value, identifying the value stream, creating flow, working according to the pull principle, and striving for perfection – what do these steps actually mean in practice? And how can the concept of lean management be implemented based on these principles?

Before we dive in, a quick note: sometimes you’ll hear people talk about 8 lean principles instead of just 5. In most cases, they’re actually referring to the 8 types of waste identified in lean methodology.

Lean principle #1: defining value from the customer’s perspective

The first core idea of lean thinking is to place customer value at the centre of all considerations. The project is viewed from the client’s point of view to gain a clear understanding of their expectations and priorities.

This makes it possible to identify:

Once these values are defined, the project strategy and parameters must be aligned accordingly. This ensures the final product fully meets customer expectations – while also avoiding unnecessary efforts that do not contribute to those goals.

Defining Customer Value in Construction

In construction projects, the target group is typically the building owner or the future users of the facility. The project must therefore be tailored to their specific needs. Here are a few examples:

1. To create affordable housing, it’s crucial to stay within budget while building quickly and energy-efficiently.

2. For a government building with a representative function, architectural design may be a key priority.

3. A major financial institution planning new headquarters might place special emphasis on sustainability and ESG construction standards.

Depending on these expectations, the project workflow can be adjusted to focus on the individual objectives.

Lean principle #2: identifying the value stream

The value stream includes all steps required to deliver the defined customer values. Through value stream mapping, companies can set the right priorities and uncover inefficiencies in their processes. All activities are typically categorised into three types:

The first category – value-adding activities – should receive the most attention, as they directly contribute to fulfilling customer needs. Necessary but non-value-adding activities must be carried out as efficiently and minimally as possible. Unnecessary activities, on the other hand, should be eliminated.

Value Stream in Construction Projects

On construction sites, the construction sequence is analysed for inefficient processes – for example, administrative tasks should be completed with minimal duplication of effort. Value-adding activities are given priority: if budget control is a key concern, then cost management becomes the central focus.

Lean principle #3: optimising the flow of processes

A core objective of lean principles is to ensure seamless, uninterrupted workflows. The value stream should move continuously through each phase of the project without obstruction, backlog, or overload. Achieving this requires close coordination between all project participants.

The following types of waste should be avoided to maintain flow:

- Errors and defects

- Overproduction

- Excess inventory

- Waiting times

- Unnecessary transport routes

- Inefficient movements

- Overly complex processes

- Underutilised talent

Ensuring flow in the construction process

On-site, any factor that obstructs the flow of work must be eliminated or avoided. This includes scheduling conflicts and idle times, construction defects requiring rework, unnecessary duplication in project coordination, avoidable trips to and from the site, or skilled workers being pushed to their limits.

Lean principle #4: pull – aligning with customer demand

The pull principle is based on a straightforward idea: only produce what the customer actually needs – and only when it is needed. This avoids overproduction. While this concept is especially relevant in manufacturing, demand-driven workflows are essential across all industries.

In the context of construction, the project timeline is dictated by the client’s needs – without imposing internal goals or schedules (as is often the case in push-based approaches). Projects are often structured in reverse: downstream activities “pull” upstream tasks as required.

Applying the pull principle in construction projects

In the construction industry, the pull principle can already be applied by ensuring that projects are only initiated where real demand exists. Within a single project, it might mean that the next trade (or the client) defines when and which outputs are needed from the previous trade.

For successful implementation, regular coordination between the project manager, stakeholders, and the client is essential.

Lean principle #5: Kaizen (perfection) – striving for continuous improvement

The Japanese term “Kaizen” stands for continuous improvement – and that’s precisely what the fifth lean principle is about. The previous four principles – defining value, analysing the value stream, ensuring flow, and aligning with demand – must be reviewed and refined on an ongoing basis.

This creates a continuous cycle of improvements that, in principle, never ends. After all, there are always new technologies, methods, and ideas that can be used to further optimise well-established processes.

Kaizen on the Construction Site

A simple example of striving for perfection is the digitalisation of the construction sector. The integration of digital tools holds enormous potential for saving time and reducing costs.

Anyone aiming for perfection in construction processes should familiarise themselves with concepts like Building Information Modelling (BIM) and the digital construction site. And with ongoing technological progress, many more opportunities for improvement are yet to come.

Benefits of Lean Management principles in construction

The five principles of lean management offer a wide range of benefits for the construction sector, leading to more efficient and effective project execution. Some of these advantages have already been mentioned, but here’s an overview of all key benefits:

Challenges in implementing Lean principles

While the benefits of lean management are well established, implementation is not always smooth. Lean is a philosophy that must be understood and supported by every member of the team. Before the principles can be applied successfully, internal resistance must be overcome.

Here’s what you need to be keep in mind:

Agile construction management based on Lean principles

In construction, lean management principles offer significant potential for saving time and effort – particularly in administrative tasks: supervising the site, communicating with stakeholders, tracking schedules, identifying and resolving defects, and maintaining clean documentation. All of these can become time sinks without the right approach.

That’s why our construction management software is built around the lean philosophy. BauMaster ensures streamlined, waste-free processes by enabling you to:

Ready for the future with Lean principles

Lean principles are not just for large-scale manufacturers like Toyota. Companies of any size can benefit and implement tailored improvements. One key message applies to all: never stand still. No one can predict which technologies and developments the future holds—but with the lean approach, you’ll be well-prepared.

FAQ – Frequently asked questions on Lean Management principles

What defines the Lean Management principle?

Lean management is an approach that aims to eliminate all forms of waste. It seeks to optimise and streamline processes so that the desired level of quality is achieved with the least possible time and cost expenditure.

What is the Kaizen principle?

Kaizen is a Japanese term that means continuous improvement. It involves the constant questioning, reassessment, and optimisation of processes and workflows – whether within a company or a specific project.

Who invented the Lean principles?

Lean management and its core principles were originally developed

by the Japanese car manufacturer Toyota

. Production manager Taiichi Ōno created the Toyota Production System (TPS) to eliminate waste in all areas – from manufacturing to services and administration.